Undercutting mortar K70 Bruil

Undercutting mortar K70 Bruil

Undercutting mortar K70 Bruil

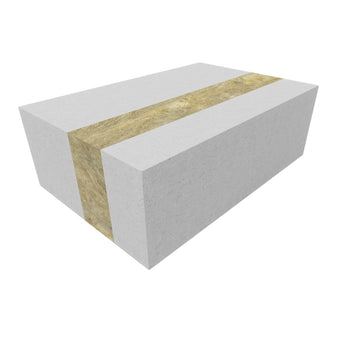

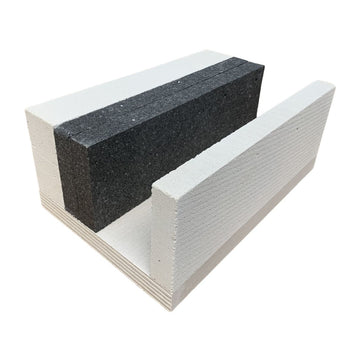

Undergrouting mortar K70 is a mortar with which you fill small spaces between, for example, (prefabricated) construction components. This can be, for example, a gap between a steel beam and a wall or joints between prefabricated concrete elements. These small spaces must be filled so that a solid and stable construction is created.

Undergrouting, the filling of small spaces between structural components, is also known as undergrouting, underchewing or chewing.

The K70 underlayment mortar is available in 25kg bags and can be ordered individually.

Why underlay with underlay mortar K70 and not mortar?

The spaces that are under grouting are subjected to great pressure. That is why it is important to use a mortar that can withstand this. The undergrouting mortar K70 from Bruil was specially developed for this. The mortar has a high compressive strength, which makes it perfect for filling small spaces between construction components.

As mentioned, the pressure load per mm2 is extremely high when underlaying (prefab) construction components. The underlayment mortar K70 has a compressive strength of 70N/mm2. An ordinary mortar is not suitable for this because it cannot absorb the pressure, it does not meet the strength class.

The average compressive strength of a regular mortar is 5 to 10 N/mm2. This is a lot lower than the underlayment mortar K70 which has a compressive strength of 70n/mm2. In addition, a regular mortar is not shrink-free and often sags a little after application. This causes cracks to form. The underlayment mortar K70 has a fast strength development, is low-shrinkage and does not sag. In this way, the whole is more stable and the chance of a cold bridge is less.

How to apply underlay mortar?

Underlayment mortar K70 Bruil is supplied in 25kg bags, all you need to do is add clean tap water.

Important during processing:

- The ambient temperature may be 5 to 30 degrees during processing of this mortar.

- Not to be used on frozen surfaces

- Process the underlayment mortar within 20 minutes

- Do not mix old and fresh mortar

- Ensure good compaction of the processed mortar. You do this by tapping the mortar

- Clean the tools with water immediately after processing

Download the technical data and safety instructions from the supplier

Preparation

- Remove anything that could adversely affect the bond

- Moisten the surface with (clean) water. This prevents the mortar from drying out

- If necessary, remove any excess water

Per bag of 25kg:

- Add 2.5 to 2.8 liters of tap water to a clean tub or mortar mixer

- Gradually add the mortar to the water

- Mix the whole for about 3 minutes. Do this mechanically with a mixer that is suitable for mortar. Do this until a lump-free, earth-moist substance has formed.

After processing

- Protect the processed mortar against weather influences that could be detrimental to its quality, such as rain, draught, sun and frost.

- Make sure that the mortar cannot dry out. You can do this by covering the surface with a foil. It should be moistened regularly. This can be done with tap water or by means of a curing compound.

How much underlayment mortar?

One bag of Bruil K70 underlayment mortar yields approximately 12 litres of mortar. Consumption depends strongly on how the mortar is applied.